HVP V1

OCTOBER 10, 2020

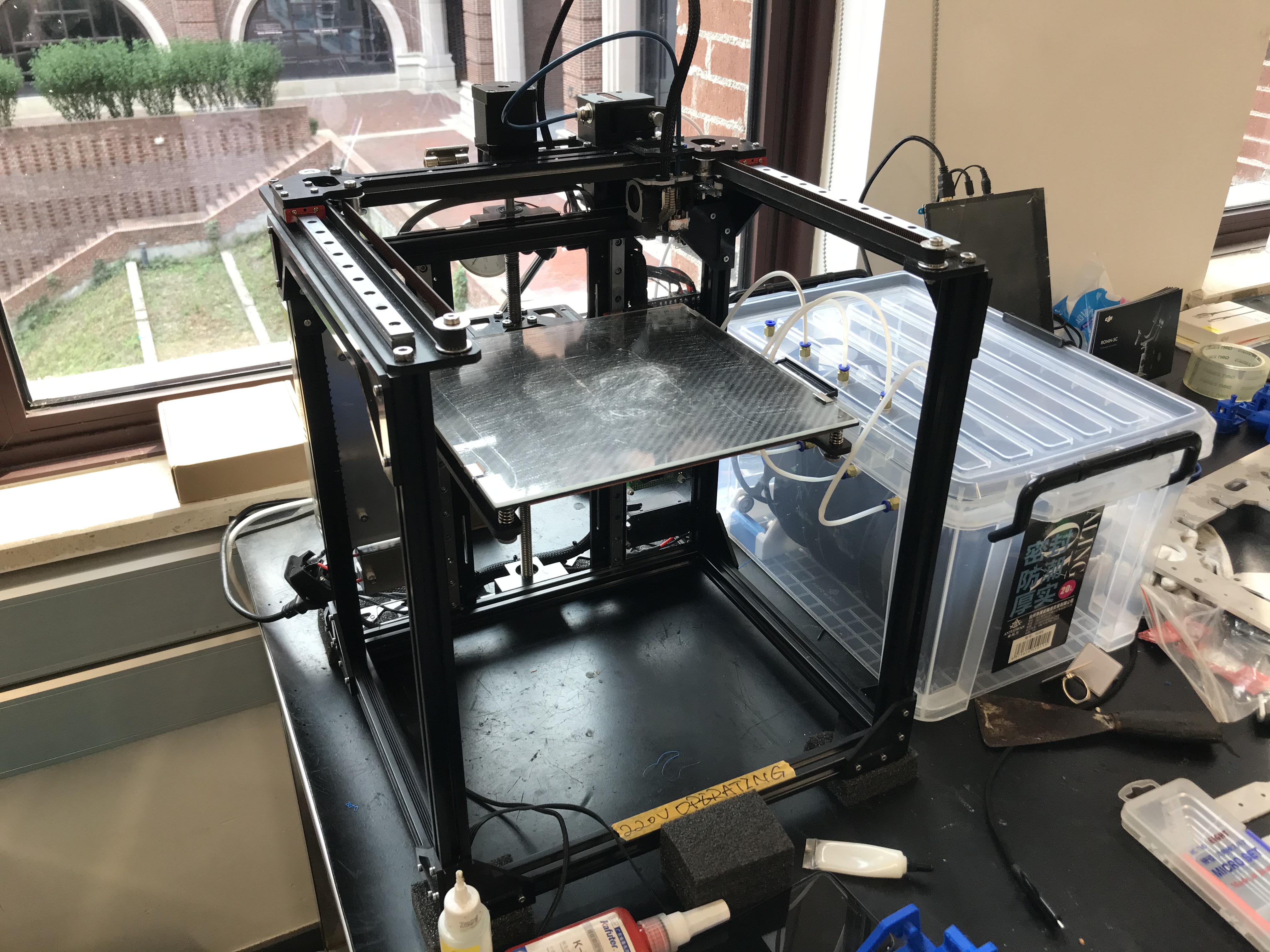

This is the first generation of the hyper-velocity printer. A lot of time was spent designing, manufacturing, and tuning the printer. Most of the parts were manufactured using the MPCNC. The printer was aimed to achieve a considerably high printing speed. However, the printer was eventually disassembled for the second generation because of the design flaw on the Z axis.

These are the hardware bought online. I chose a set of SKR V1.3 and raspberry pi as controller and actually brought a mosquito hot end from U.S. There's also a set of close-loop controlled NEMA23 stepper motors and PCB for stepper driver converting that made by myself.

I made most of the parts by the MPCNC and spent a lot of time optimizing the machining process for better quality and shorter manufacturing time. In the picture is the x carriage manufactured by MPCNC.

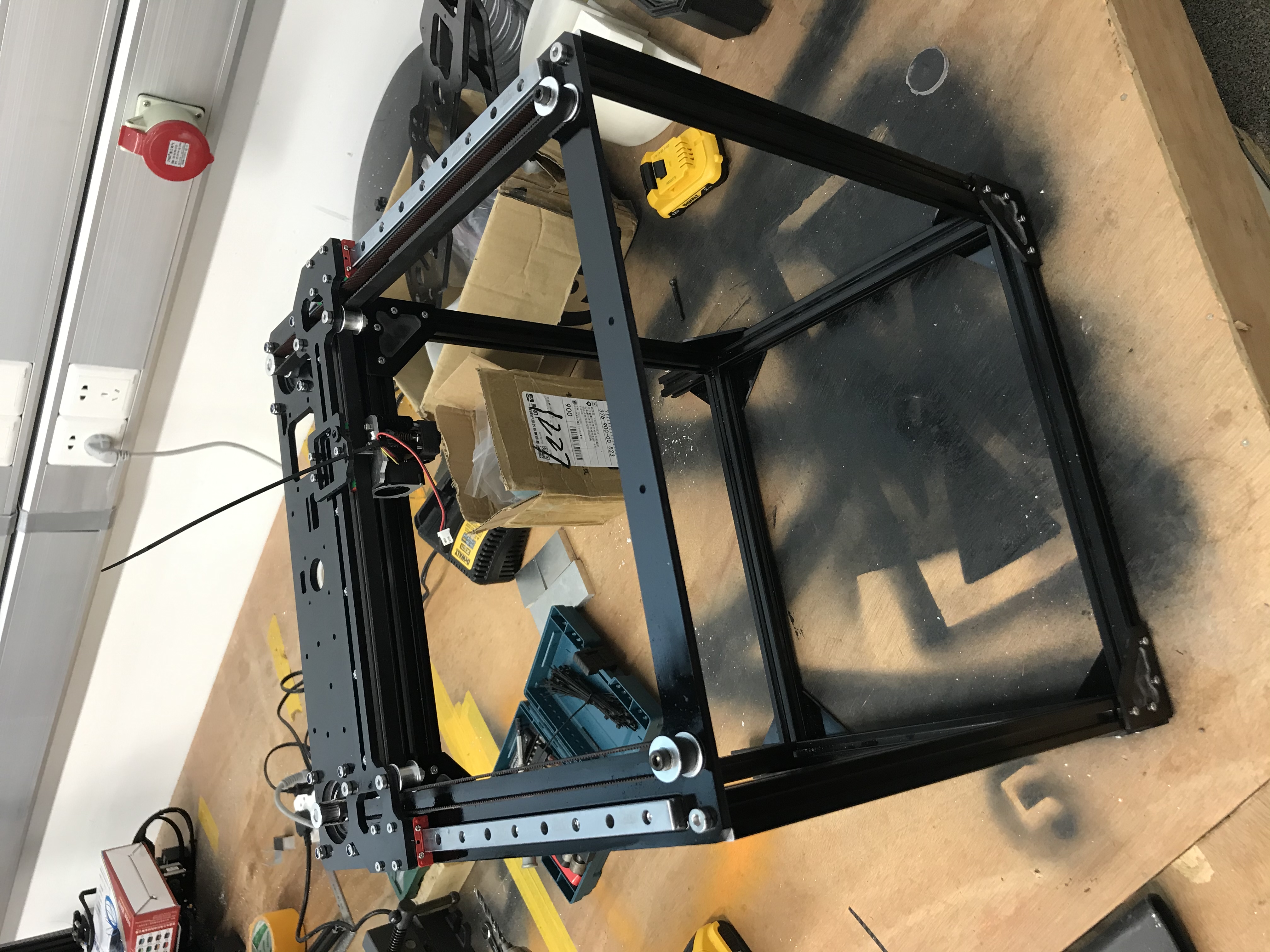

Most of the printer frame was manufactured with black FR4 fiber glass boards. The FR4 has similar property with carbon fiber board but with a much cheaper price and around 30% more weight. Also, the FR4 is more friendly to manufacture as the dust does no harm and settling much faster than carbon fiber.

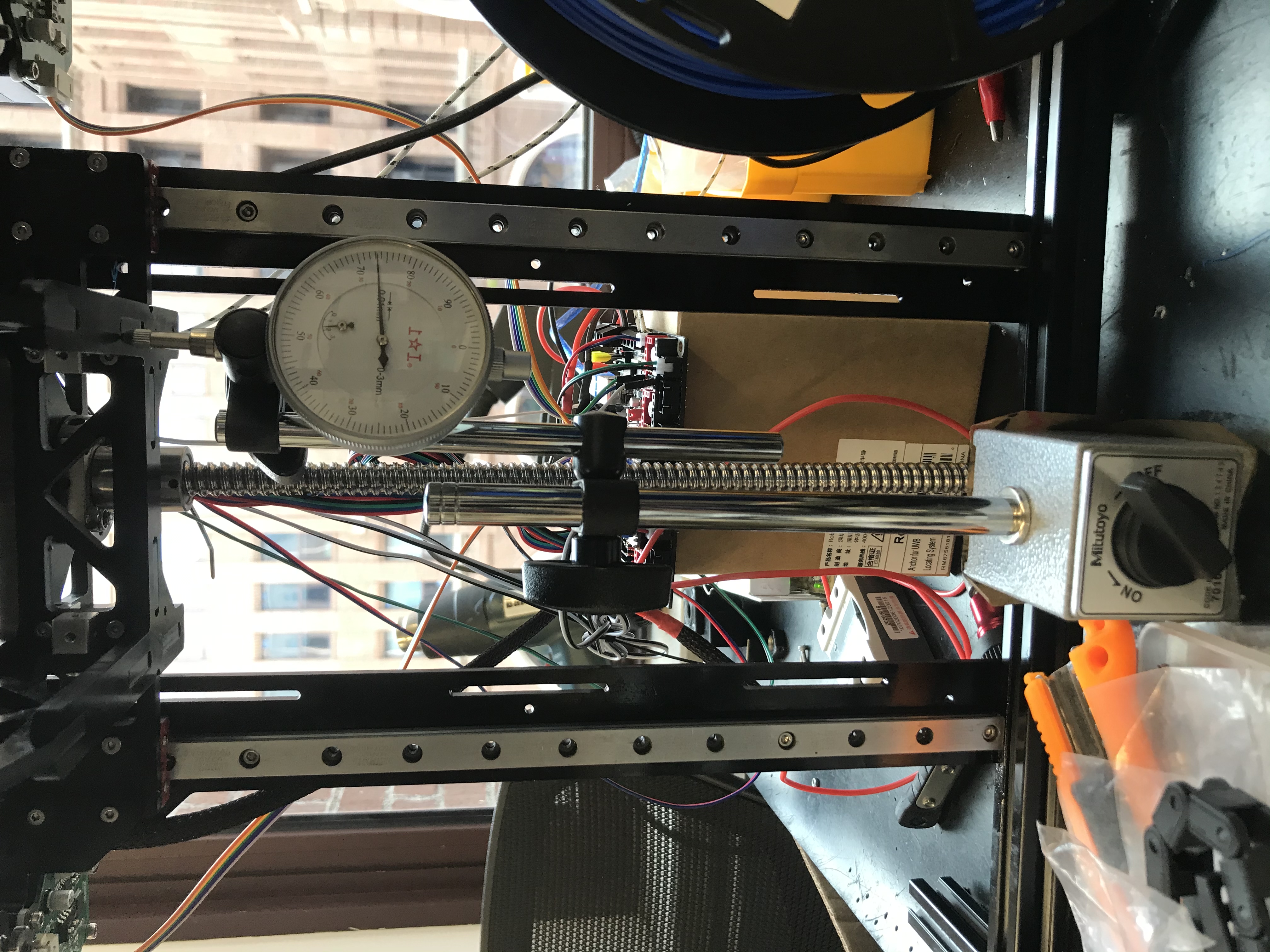

Just want to show off the perfect wiring. :) So things in this picture worth sharing are the customized PCB boards for stepper driver converting on the top right of the SKR and customized lead screw which is different with the previous picture. So the reason of switching to regular lead screw instead of the original ball lead screw is the ball lead screw creates a periodic horizontal shift every rotation. And since the tolerance of the ball lead screw is much smaller than the regular lead screw, the shift was transferred to the printer bed, and it created a periodic layer pattern on the print part.

So I found the problem by using a dial gauge. There was actually some uneven vertical error every z move as well as the tolerance on the ball lead screw is so small that it drove the two linear rail unevenly. Therefore, after trying several solutions such as adding springs between the leading nut and heat bed as the previous picture shows, I found my self more into the 3Z self-leveling design. So the first generation of hyper velocity printer was very unfortunately disassembled for its successor.

After around half a year after I took the printer apart, HevORT on YouTube (MirageC now) post a video about the horizontal shift on the ball lead screw. The cool dude designed a quite good solution to the problem. Link to YouTube video.